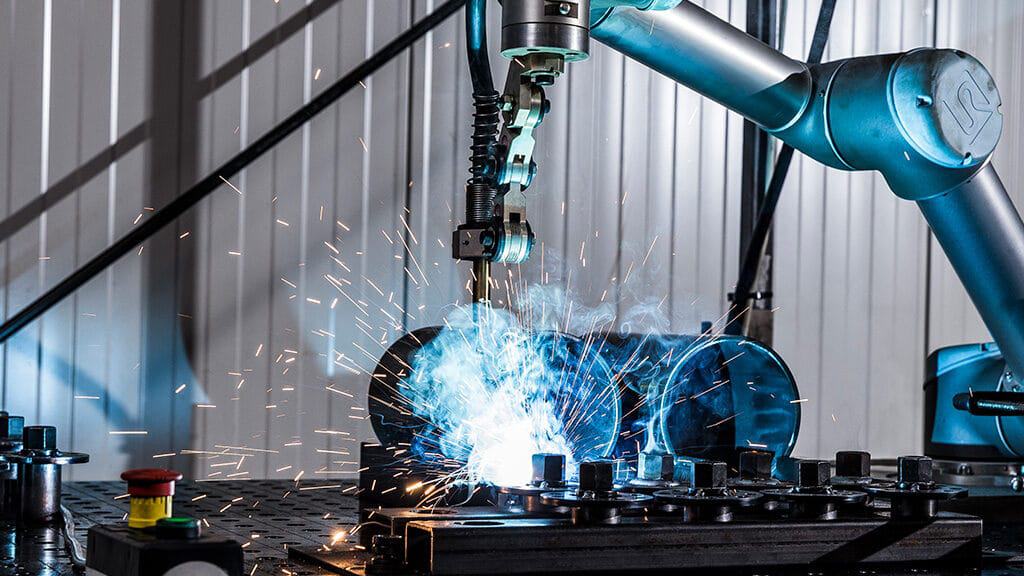

The CoWelder is an easy-to-program collaborative welding robot, designed by Migatronic. We have combined the best and latest welding technology with the most innovative robot technology. CoWelder is based on the Universal Robots platform of collaborative robots and our high-end welding machines and welding technology.

Table of Contents

What is a collaborative robot?

A collaborative robot or cobot is designed to work together with humans in a shared workspace. Typical features are soft edges and limitations of speed and strength. A resistance sensor automatically stops the cobot at a resistance of 8 kg m/s. This makes it safe for humans to work closely together with the cobot.

Differences between traditional industrial robots and the CoWelder

An industrial robot requires safety fencing and is not designed to operate close to humans. In spite of that, safety requirements for collaborative robots are much more stringent. That is why the CoWelder has more than 15 advanced safety functions. It is designed to operate close to and together with humans. This means that a welder and the CoWelder can operate simultaneously at a welding table.

Another advantage is that it takes little time to install a cobot in an existing production. After a few hours training, you will be able to program the robot for most welding assignments. Programming incorporates the movements of the robot and the settings of the welding machine into a complete program for welding a workpiece. Depending on the complexity of a workpiece, it will take an experienced operator approx. 30 minutes to program it.

After programming and test, you can save the program in the robot’s memory. Next time you are to weld a similar workpiece, you can activate the program, and the CoWelder can resume production. You can store numerous programs and easily export them via a USB device. This means that you can create programs on one solution and easily export them to another. Note! We recommend that you test the programs before using them on other cobots.

CoWelder

- Cheaper alternative for companies wanting to automate parts of their production.

- Can improve your small batch component production.

- Operators can stay close to the robot during operation.

- After a few hours’ training, anyone can program the robot for new assignments. Programming time per workpiece: approx. 30 minutes (depending on complexity of workpiece)

- Easy set-up: start welding on the first day.

- Mobile and flexible: move it to other workstations in your production and set it up for different assignments.

- Make the most of the space.

Industrial Robot

- Higher price, but usually also higher automation percentage.

- Ideal for large batch component production.

- Operators must stay outside the robot’s safety fencing during operation.

- Programming new workpieces requires skilled robot operators.

- Set-up and implementation time-consuming

- Heavy and stationary.

- Takes up space owing to safety guard and large fixtures.

VM Tarm produces 250 customised tank trucks every year. The CoWelder Migatronic welding equipment made it possible to automate a small-batch production, lower the cost price and improve the quality. Get the full story here

The CoWelder is ideal if …

You produce at full capacity most of the time but you still have unused capacity. Consequently, you want to automate all or part of your welding production. You want to improve efficiency and competitive power by welding more components in a better quality, at higher speed and at lower cost. You want to improve ergonomics for your skilled welders by relieving them of repetitive work, which the CoWelder can take on. This releases staff for other, more complex assignments and increases your capacity.

You manufacture large products in your business, e.g. containers, boilers or components for ships. Perhaps you already have industrial robots in your production. Still you are also dependent on sub-supplies of components for one or several steps in your production, and this increases your costs. Let the CoWelder take over your small batch component production and keep your production under your own roof.

There is a general lack of qualified welders, and this means capacity problems for companies in growth. To offset this, many companies turn to automation, which is costly in terms of both time and resources. The CoWelder provides an extra arm in your production at 7 Euro/h* and only requires a co-worker to feed it with the components to be welded.

*Depends on individual leasing agreement

You wan’t to retain skilled staff. The CoWelder makes your business grow, and nothing indicates that the robot means staff reduction. On the contrary, skilled welders avoid spending time on routine tasks and can instead carry out tasks that call for a greater extent of welding expertise. Moreover, it relieves staff of exposure to direct radiation and welding fumes.

Build your own CoWelder in the CoWelder Configurator

Czech

Czech Danish

Danish Dutch

Dutch French

French German

German Hungarian

Hungarian Italian

Italian Norwegian

Norwegian Polish

Polish Spanish

Spanish Swedish

Swedish