CoWelder is the simplest automated welding solution on the market

Integrate CoWelder in your production with minimum deployment time. Improve your productivity significantly without having any experience with automated welding.

Reduce production lead time

Get a flexible scale production

Ensure uniform welds

Free your welders

Consisting of leading edge technology, honed for efficiency

CoWelder’s core components are made up of excellent technology. The result is a welding solution that becomes more than the sum of it’s parts. Fantastic welding capabilities mixed with the agility and safety of the collaborative robot simply lifts all aspect of welding production.

Uncompromised welding

Top-of-the-line Migatronic welding machines are the core of CoWelder. Choose MIG/MAG or TIG welding proces.

Software assisted

Clever software functions lets you tackle the hardest challenges and speed up your welding workflow.

Innovative robot technology

The robot arm is the innovative collaborative robot from one of the world’s leading developers and manufacturers – Universal Robots.

A great workstation

Best-in-class welding and fixture table can be included with CoWelder solutions.

Increase your arc time

Every minute your arc is off is unproductive. CoWelder will get the job done faster than any manual welder could ever do.

It will give your welding production more arc time. Every movement is fine-tuned towards spending just the needed time on each weld.

CoWelder utilises 6 axes to move around the workpiece during welding. This agility and reach allows the robot to keep welding where a human arm with only 3 axes would need to stop to reposition

CoWelder can reach over double that of humans. It can keep welding for long stretches without reducing accuracy or having unnescessary start/stop.

CoWelder will not make any stop and start in the middle of a weld. It will skip the detours and only make the most necessary torch movements. It will finish multiple workpieces without stopping.

If your workpiece is small, place more workpieces in the reach of CoWelder and save valuable time. Combined with the Offset-function, arc time/hour will increase significantly.

Scale your production as needed

CoWelder brings a new definition to the word flexibility in modern day industrial production. It is so easy to switch over the production that it pays off to automate welding of simple workpieces no matter the quantity or frequency. Be able to weld workpieces for specific orders at peak points or produce for stock at low volume times.

Weld small or large batches and often or rarely recurring tasks. Upscale and downscale quickly when necessary. Simply adjust the production to your orders.

Perfect welds every time

Automation is the ultimate risk-mitigation strategy for your production. We prioritize meticulous documentation of your workpieces and the technical aspects of each weld, ensuring seamless continuity even in the face of key staff member turnover.

With our solutions, you can safeguard your production against disruptions and confidently maintain uninterrupted operations.

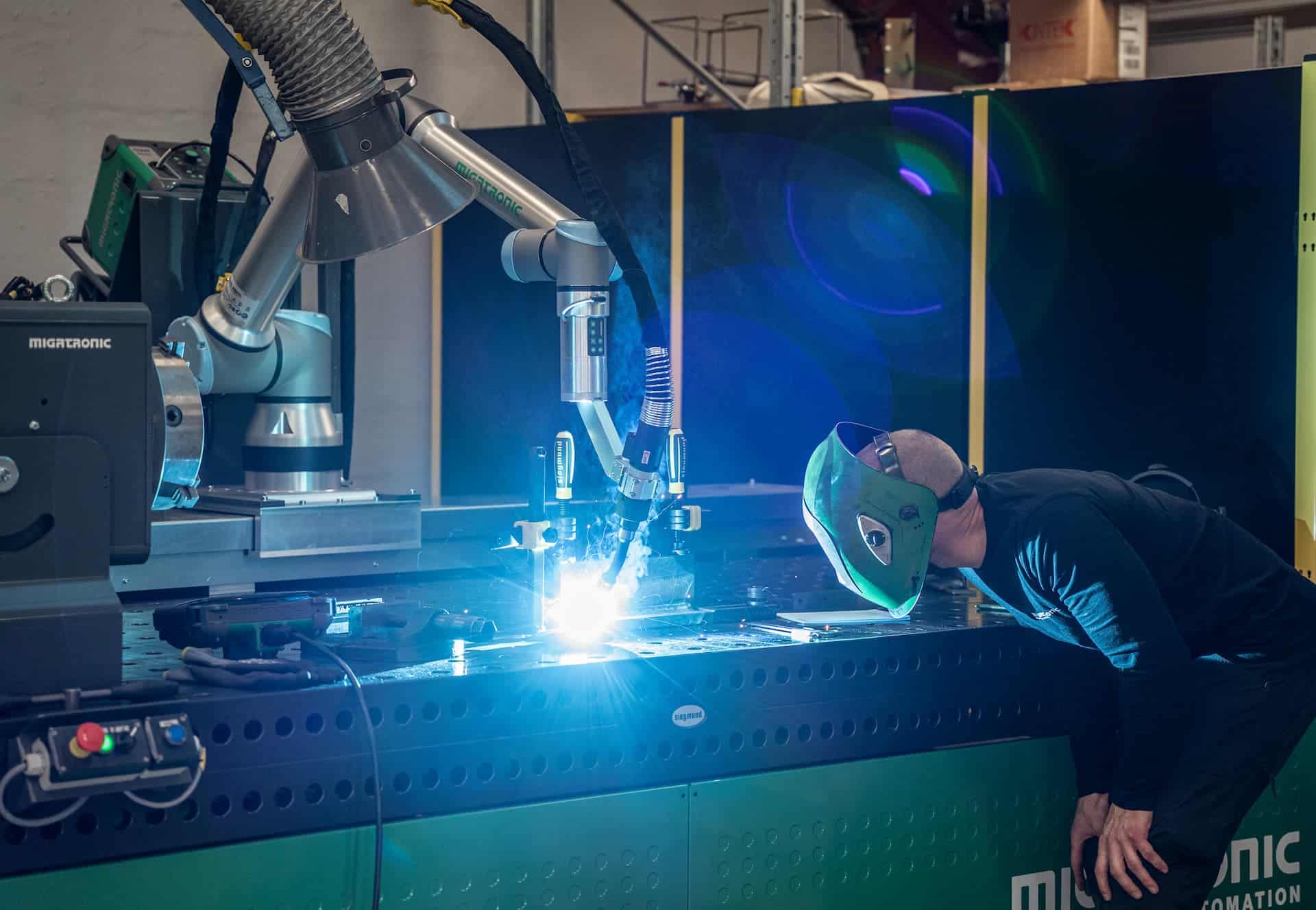

Leave the dull stuff to the robot

Minimise monotonously repeated work and let the cobot take over the dull routine jobs. Utilise the know-how of your skilled welders for the complicated tasks instead.

Optimises work processes in close collaboration with welders.

Prevent repetitive strain injury (RSI)

Reduce exposure to UV/IR radiation and fumes.

Reduce sick days.

Increase job satisfaction

“I worked as a welder for many years and at some point, my job got dull. It was too much of the same. That is why it was an interesting challenge for me to be included in the CoWelder project. It is safe to say that working with the CoWelder, I rediscovered how fun work can be.”

Serving many usecases through diverse configuration options

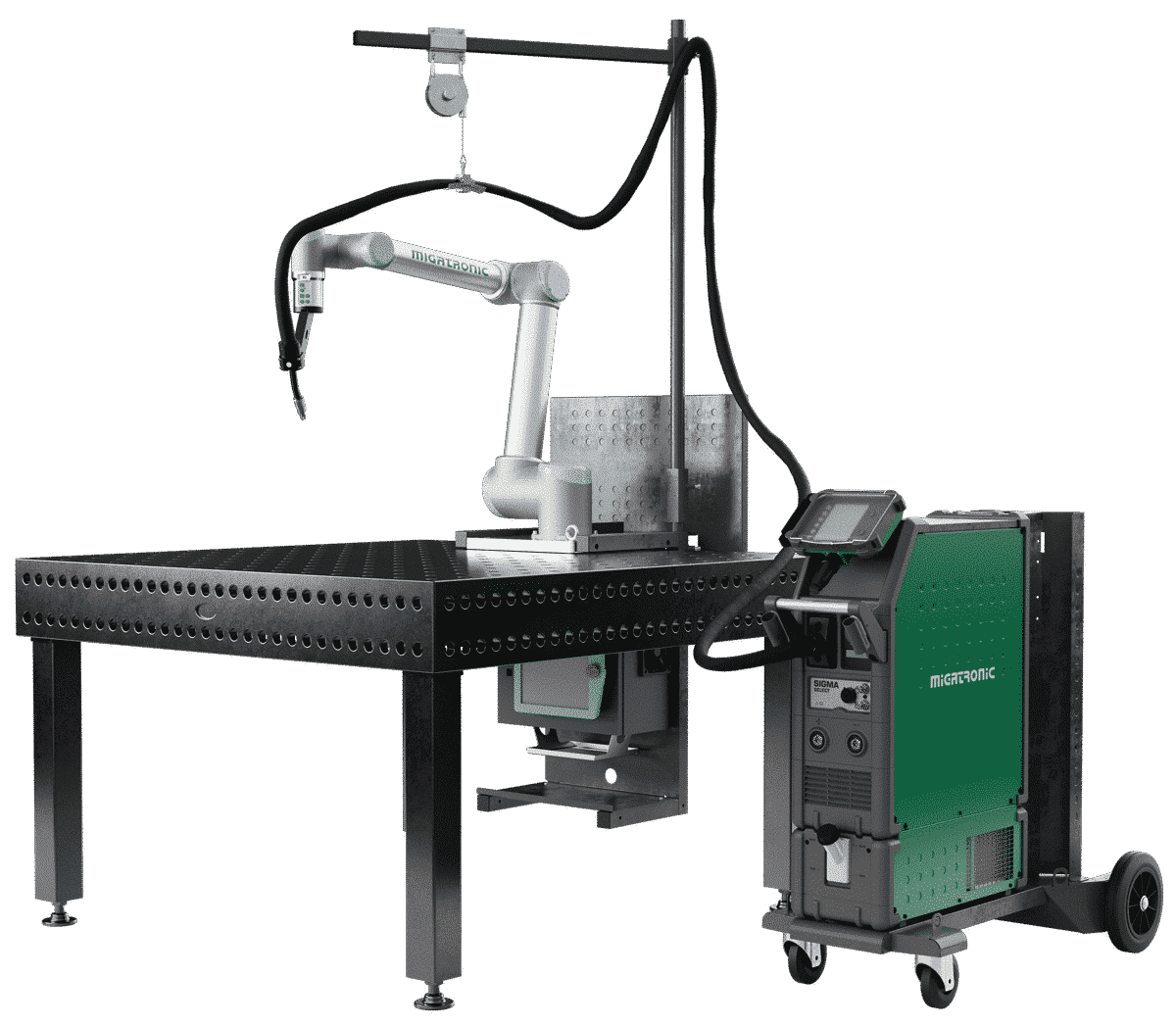

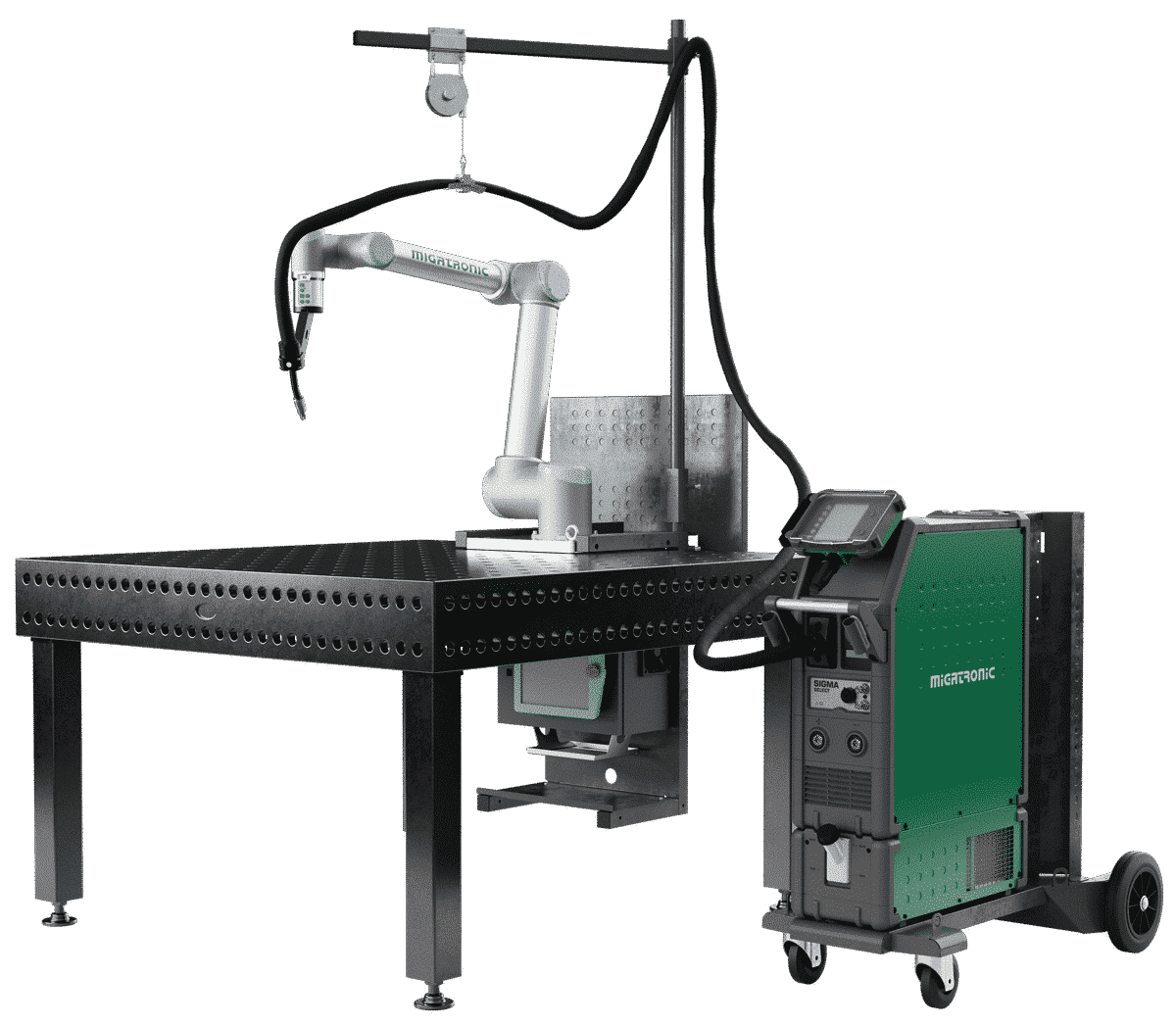

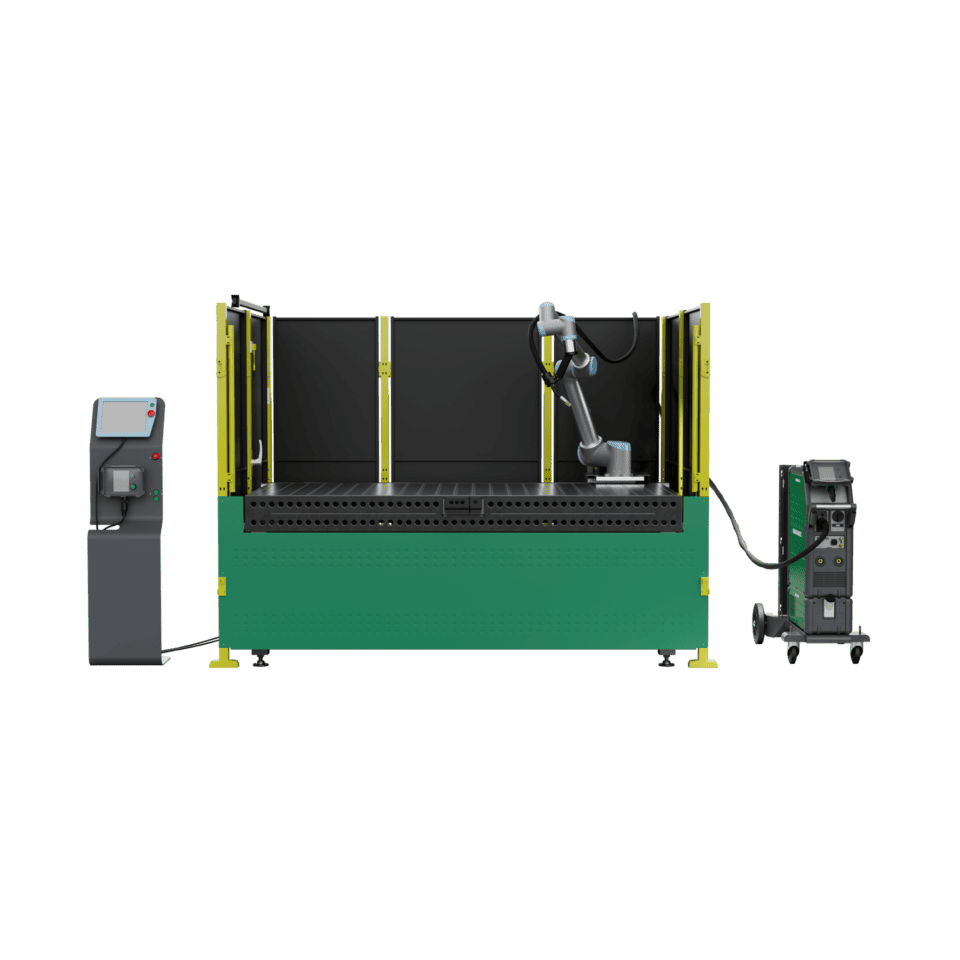

CoWelder Basic

The basic edition of CoWelder consist of best-in-class welding power source from Migatronic and Universal Robot’s cobot UR5 or UR10 running on proprietary Migatronic UR Caps (software) to easily control movement and welding.

We recommend also getting a Siegmund welding table in system 16, 22 or 28 (sold as part of CoWelder solution), to have the best possible foundation for the CoWelder to work on.

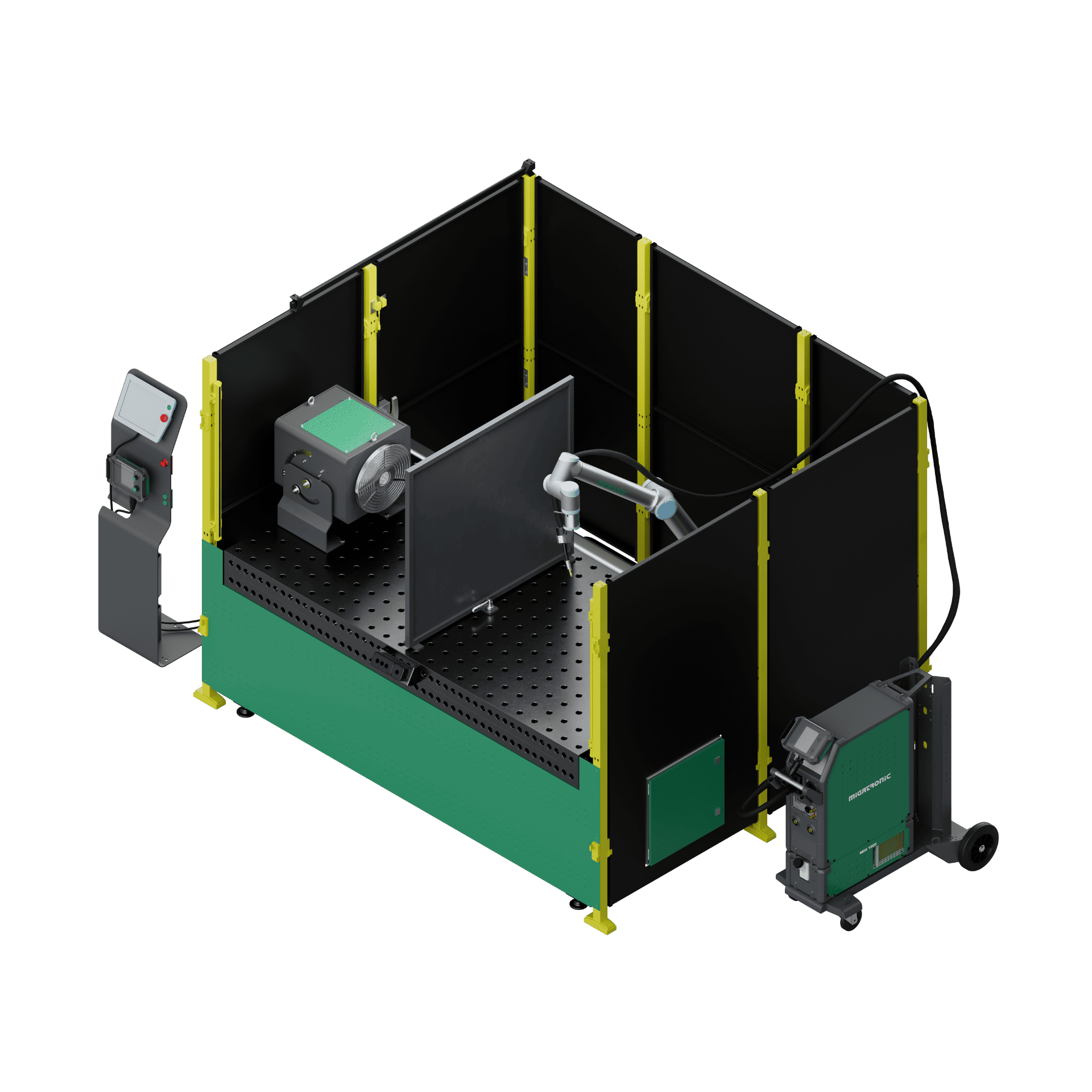

CoWelder 360

CoWelder 360 provides a 360° working area for the robot.

- Collaborative welding robot with a 360° range

- Increase arc time for improved productivity

- Flexible and scalable production setup

- Create high-quality welds effortlessly

- Free welders from repetitive tasks

CoWelder 360 offers a seamless integration into your production, delivering faster and more efficient welding results, enabling you to redefine flexibility in modern industrial production.

CoWelder Combi

CoWelder Combi offers the unique capability of welding both MIG/MAG and TIG within a single robot solution.

With a CoWelder capable of both MIG and TIG welding, you can handle a broader range of welding applications. It allows you to work with various materials and thicknesses, making the robot suitable for a wide range of projects.

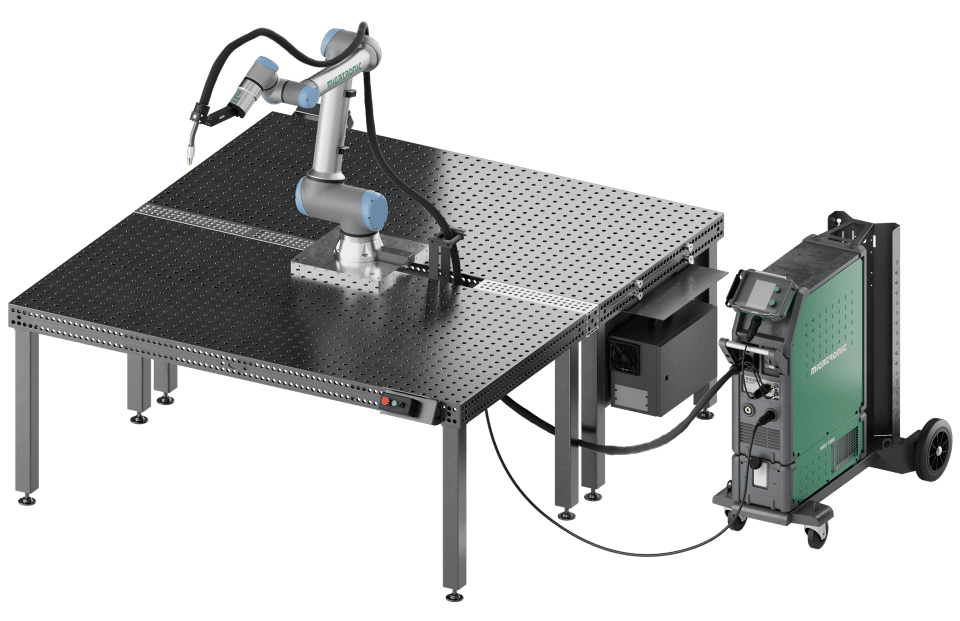

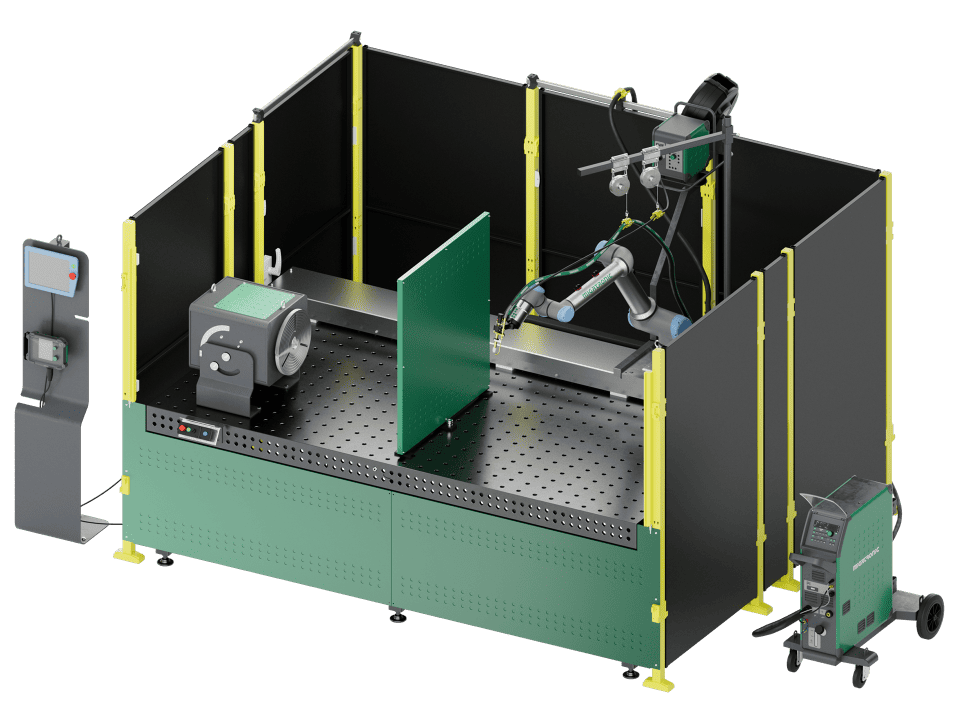

CoWelder Track

The track edition offers an integrated track system which allows the robot arm to move sideways along the welding table, increasing its effective reach. This enables welding of more identical or larger workpieces at once.

By adding extra equipment, you can expand the range of applications and future-proof your production. An optional turntable, for example, allows manipulating the workpiece during welding, giving extra flexibility to the already flexible welding solution.

Moreover, the table can be divided into two workstations using a partition wall. This allows the operator and the CoWelder to switch places efficiently. While one workpiece is being welded, the next one can be prepared simultaneously.

Best-in-class welding capabillities

Sigma Select

No welding proces can match MIG/MAG welding. Neither when it comes to speed, efficiency or quality. Sigma Select is the right pairing for a MIG/MAG CoWelder.

PI TIG 350 AC/DC

Sophisticated TIG welding power source – with cold wire feeding. When you need to TIG, PI 350 AC/DC is the perfect match for CoWelder.

Welding software

Migatronic’s exclusive welding functions such as Power Arc Pulse and IAC as well as all synergic welding programs can be utilised with CoWelder.

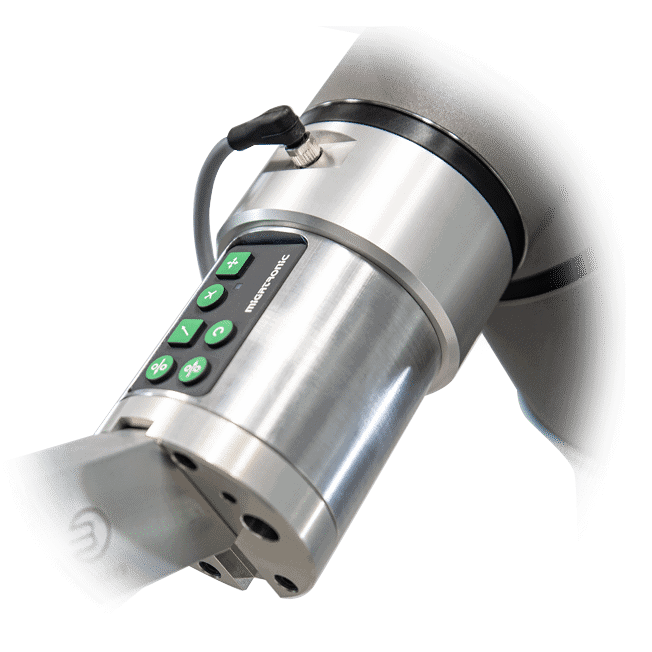

Miga Smart Tool lets you guide the robot arm with your hands

Watch the video to see how it works.

Freedrive

Airpoint

Linear Welding Point

Circular Welding Point

Unique software functions that let's you do more

CoWelder revolutionises welding through automation. But that's not all. Our custom software brings the smart functions of industrial robots to CoWelder, enabling you to take control of your work like never before.

Offset

With Offset, you can copy an entire workpiece. You only have to construct the workpiece once, and register the physical location of the next workpiece. The weld is then duplicated without you redoing all the steps. This time-saving function reuses settings and patterns for efficiency.

Weaving

With Weaving, CoWelder makes the torch able to fill a V-seam. The torch makes a zig-zag movement along the joint, and in that way, extends the size of the bead width.

Cladding

With Cladding, it is possible to use CoWelder for easily adding a layer of material onto the base material. This layer can serve various purposes, such as enhancing the material's properties, protecting against corrosion, or altering the appearance.

Spot welding

With Spot Welding, the insertion of spot welds is automated, eliminating the need for manual construction in the weld program. Simply input the spot weld length, number, start and end positions, and the robot accurately calculates the spacing and placement.

Touch Sensing

With Touch Sensing, the CoWelder adjusts the position of the torch before it starts welding by physically touching the workpiece. The result is a more consistent weld and fewer defects, if slight deviations appear in workpieces for a specific weld item.

Seam Tracking

With Seam Tracking, CoWelder automatically makes instant weld seam adjustment. The process corrects for slight deviations or variations in the welded item during welding.

Czech

Czech Danish

Danish Dutch

Dutch French

French German

German Hungarian

Hungarian Italian

Italian Norwegian

Norwegian Polish

Polish Spanish

Spanish Swedish

Swedish